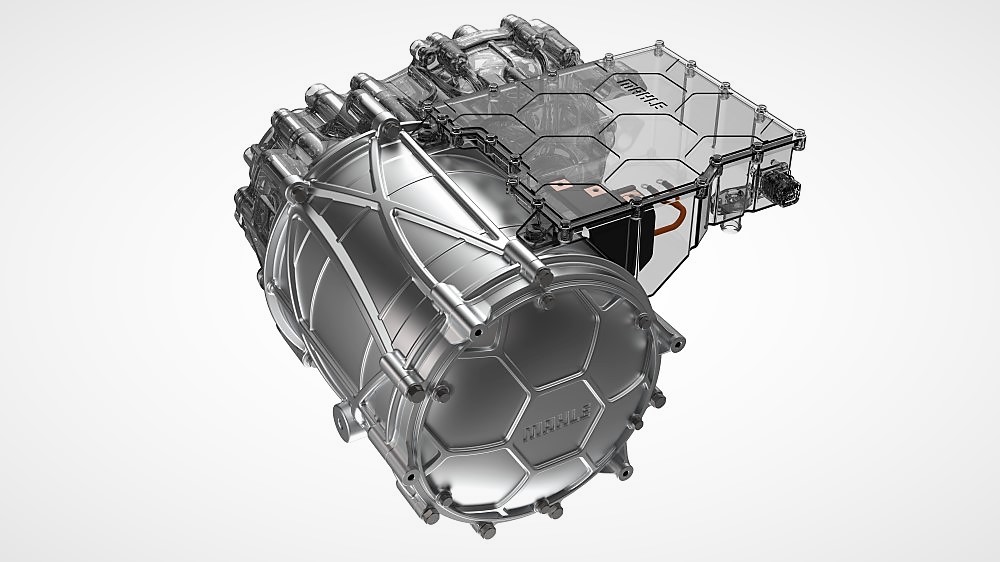

Mahle Making Groundbreaking Magnet-free Electric Motor

As the first of its kind; the high-efficiency motor is cheaper to produce, durable, and does not use any rare earth elements.

German company MAHLE has been one of most interesting companies in electrification. As an automotive development partner and supplier, Mahle has focused a great deal of their resources on EV and future tech. They have quietly become a major force in the aftermarket industry. In keeping with the company’s envelope-pushing portfolio, they have announced production of a new magnet-free electric motor.

Noted for their commitment to electric vehicles e-mobility, the company has innovated problem-solving technology from powertrains to A/C. But this new magnet-free electric motor is definitely all-new. Especially given its emphasis on sustainability, durability, versatility, performance, and actual affordability.

“With our new electric motor, we’re living up to our responsibility as a sustainably operating company,” says Michael Frick, Chairman of the Mahle Management Board (ad interim) and CFO. “Dispensing with magnets and therefore the use of rare earth elements offers great potential not only from a geopolitical perspective but also with regard to the responsible use of nature and resources.”

Mahle’s new kind of magnet-free electric motor does not use any rare earth elements. This makes production more environmentally friendly, and cheaper overall. One intriguing aspect of Mahle’s new motor is the inductive power transmission. This contact-free power transfer system allows for the motor to run longer and efficiently, even at high speeds.

Durability was a key factor in the inductive power. Necessary transmission of electrical currents between the rotating and stationary parts inside the motor takes place without contact and is therefore safe from wear-and-tear. This makes the engine maintenance-free and suitable for a wide range of applications.

Efficiency is another defining aspect. Teams at Mahle needed the powertrain to not only run well, but efficient. So efficient, in fact, that the engine is above 95% at almost all operating points; levels usually reserved for Formula E racing cars.

Especially surprising is the versatility. This motor can be used in a wide range of vehicles. This one-size-fits-all idea is a boon to consumers. And EV motor that can fit anything from a Fiat to a F-150, a Leaf to a Hummer EV? Yes please.

“Our magnet-free motor can certainly be described as a breakthrough, because it provides several advantages that have not yet been combined in a product of this type,” says Dr. Martin Berger, Vice President Corporate Research and Advanced Engineering at Mahle. “As a result, we can offer our customers a product with outstanding efficiency at a comparatively low cost.”

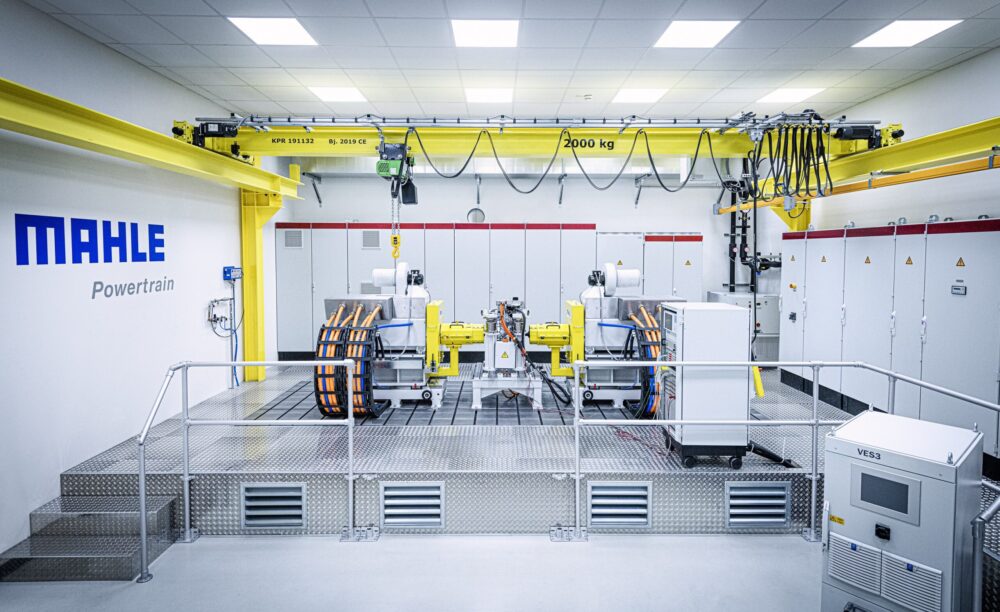

During its development, Mahle used an innovative simulation process testing various motor designs with different parameters, adjusting and modifying until an optimum level is reached. This approach is significantly faster and cheaper than conventional processes. In this way, Mahle is helping to expedite tech to get more EVs on the road.

Clearly, the team thought carefully about what drivers want. We appreciate a company taking the time and risks to develop a magnet-free, affordable, versatile, long-lasting electric power with Formula E chops intended for real-life driving situations. We will keep you updated on when the new motor is expected to hit market.

Photos: Mahle

Join the Electric Vehicle forums now!